Motor-driven butterfly valve MBV-SDⅡ-M4-ARJ Series

Long-life, Low-price, High performance, Versatile running patterns

1. Long-life 1,000,000 cycles

2. Low-price Automatic pressure control is made low-priced

3. High-performance Adopt high performance servo-motor ・ servo-amp and new driven mechanism

4. High-functionality Leakage (*Note.1) , Multi-position control, Auto pressure control

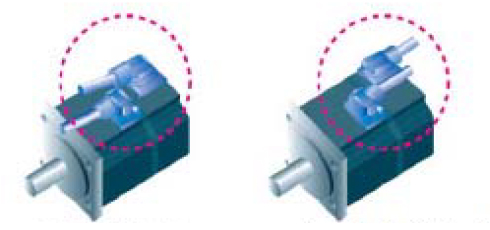

Motor position-selected (four-position)

If the minimum conductance is required, the specification with valve disc O-ring is also available.(However, it cannot be used as a shut valve.)

5.Minimum Diameter 20A, Available from NW25 size. Only 20A NW25 size can be used as a shut valve.

Characteristic

◇ The series of MBV-SDⅡ-M4-ARJ of the valve which is compatible with the low cost is a motor-driven butterfly valve of conductance control exclusive use without valve disc O-ring.

◆ A multi-purposed servomotor made by Mitsubishi Electric is being used for a drive source of valve disc.

The valve disc can be stopped and hold at fully-closed, fully –open and other any position.

◇ It is multi-stage and can change the opening area of the valve and can use it in wide uses such as the pressure variableness before and after the constant pressure maintenance in the vacuum chamber and the valve or variableness of the exhaust conductance.

◆ The position of half open can be beforehand set up by PC software or the main part of servo amplifier, and can be made for a maximum of 13 positions to memorize.

◇ Reproducibility often stops in a set position by sending a signal from a host system of PLC etc.

◆ By combining the dual automatic pressure control system controller of an option with FPC series, the variegated control including automatic pressure control is attained.

Main specification

| STD FLANGE | JIS・ISO・CF・NW |

|---|---|

| Leak Rate | 1×10-9 Pa・m3/s > |

| Pressure Range | 105~10-6 Pa |

| Disk seal | None (Leakage type) Viton O-ring(Full closed type: NW25) |

| Shaft seal | Viton O-ring two-tier |

| Diameter | 25A ~ 100A |

|---|---|

| Power | Main:AC200V (rated current 1.5A) Control:AC200V (rated current 0.2A) Interface:DC24V (max 500mA) |

| Driven mechanism | AC servo-motor |

| Gas contact material | SUS304 |

※ To improve this specification may change without notice.

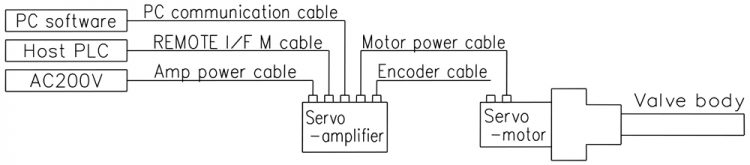

System configuration

※ Included in the valve unit:Valve body、Servo-motor、Servo-amplifier

※ Please refer to the “option list for the multi-position ” other than those above.)

* Note )1.The leakage specification (without valve disc sealing mechanism).

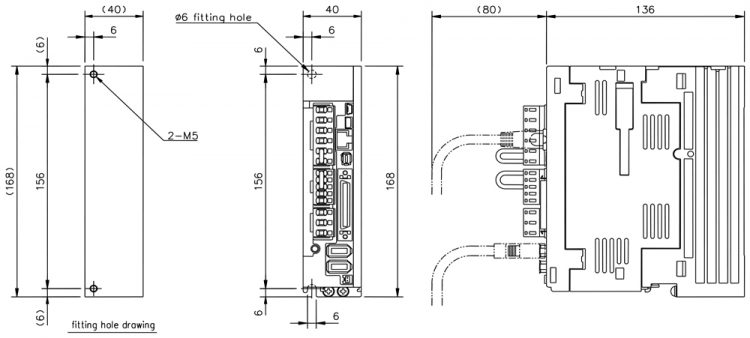

Attachment servo amplifier dimensional drawing

About the motor correspondence of those other than a standard

2-axis system configuration

We will consult also about change on motors according to the equipment usage environment of your company,

such as servo motors other than a standard motor

*Optional dual pressure controller By connecting, it can be used as an APC.

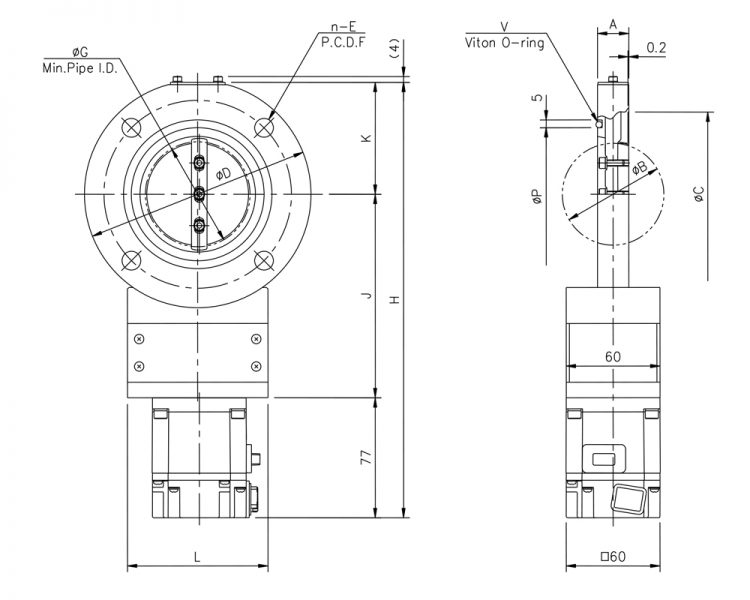

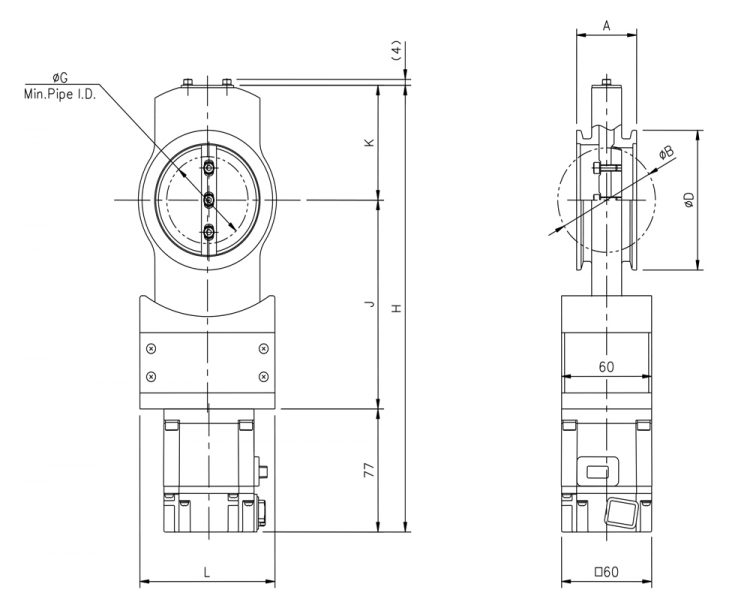

Dimensions of MBV-JIS SDⅡ-M4Series

| Unit in:mm | |||||

| Model | MBV-1SDⅡ-M4-ARJ | MBV-2SDⅡ-M4-ARJ | MBV-2.5SDⅡ-M4-ARJ | MBV-3SDⅡ-M4-ARJ | MBV-4SDⅡ-M4-ARJ |

| MOD No | 10805□□ | 10807□□ | 10808□□ | 10809□□ | 10810□□ |

| A | 20 | 20 | 20 | 20 | 20 |

| B | 34 | 52 | 68 | 81 | 104 |

| C | 58 | 88 | 105 | 120 | 145 |

| D | 90 | 120 | 145 | 160 | 185 |

| n—E | 4-φ10 | 4-φ10 | 4-φ12 | 4-φ12 | 8-φ12 |

| F | 70 | 100 | 120 | 135 | 160 |

| G | 33 | 52 | 67 | 80 | 102 |

| H | 222.5 | 253 | 278.5 | 292.5 | 318 |

| J | 102.5 | 117.5 | 130 | 137.5 | 150 |

| K | 43 | 58.5 | 71.5 | 78 | 91 |

| L | 90 | 90 | 90 | 90 | 102 |

| P | 40 | 70 | 85 | 100 | 120 |

| V | V40 | V70 | V85 | V100 | V120 |

Note1:The above Flanges are accordance with older JIS B2290 Vacuum Flange for Vacuum Equipment (Flange for affiliated book maintenance)

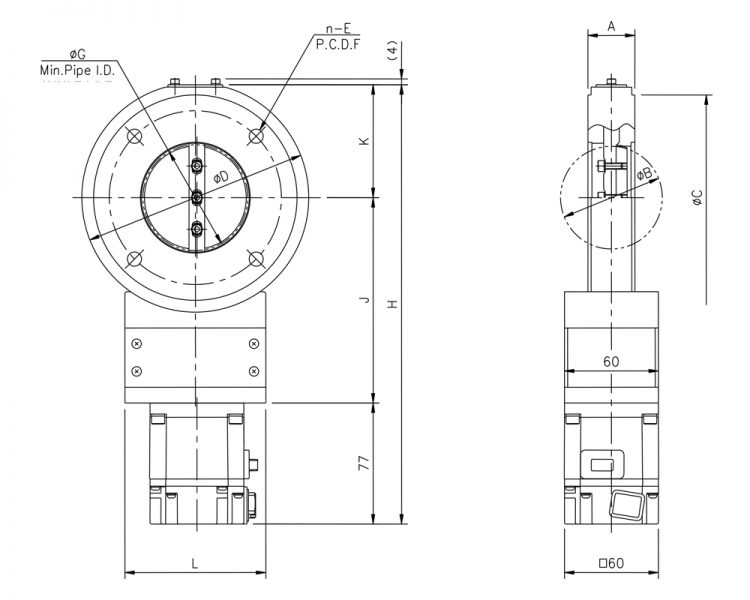

Dimensions of MBV-ISO SDⅡ-M4Series

| Unit in:mm | |||||

| Model | MBV-ISO40SDⅡ-M4-ARJ | MBV-ISO50SDⅡ-M4-ARJ | MBV-ISO63SDⅡ-M4-ARJ | MBV-ISO80SDⅡ-M4-ARJ | MBV-ISO100SDⅡ-M4-ARJ |

| MOD No | 10865□□ | 10866□□ | 10867□□ | 10867□□ | 10868□□ |

| A | 30 | 30 | 30 | 30 | 30 |

| B | 34 | 52 | 68 | 81 | 104 |

| C | 100 | 110 | 130 | 145 | 165 |

| D | 120 | 120 | 145 | 160 | 185 |

| n—E | 4-φ9 | 4-φ9 | 4-φ9 | 8-φ9 | 8-φ9 |

| F | 80 | 90 | 110 | 125 | 145 |

| G | 23 | 47 | 62 | 76 | 100 |

| H | 253 | 253 | 278.5 | 292.5 | 318 |

| J | 117.5 | 117.5 | 130 | 137.5 | 150 |

| K | 58.5 | 58.5 | 71.5 | 78 | 91 |

| L | 90 | 90 | 90 | 90 | 102 |

Note1:The above Flanges are accordance with ISO 1609 Vacuum technology Flange

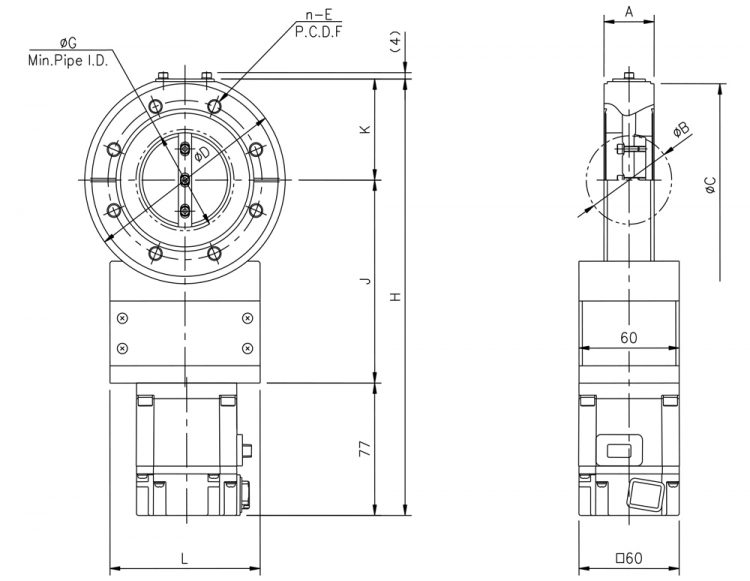

Dimensions of MBV-CF SDⅡ-M4Series

| Unit in:mm | ||||

| Model | MBV-CF40SDⅡ-M4-ARJ | MBV-CF40SDⅡ-M4-ARJ | MBV-CF63SDⅡ-M4-ARJ | MBV-CF100SDⅡ-M4-ARJ |

| MOD No | 10840□□ | 10840□□ | 10842□□ | 10844□□ |

| A | 30 | 30 | 30 | 30 |

| B | 23 | 34 | 52 | 104 |

| C | 69.4 | 69.4 | 113.5 | 151.6 |

| D | 80 | 90 | 120 | 185 |

| n—E | 6-M6 | 6-M6 | 8-M8 | 16-M8 |

| F | 58.7 | 58.7 | 92.1 | 130.2 |

| G | 0 | 23 | 47 | 100 |

| H | 212.5 | 222.5 | 253 | 318 |

| J | 97.5 | 102.5 | 117.5 | 150 |

| K | 38 | 43 | 58.5 | 91 |

| L | 90 | 90 | 90 | 102 |

Note1:The above Flanges are accordance with ISO/TS 3669-2 Vacuum technology-Bakable

flanges-Part2:Dimension of knife-edge flanges

Note2:No Groove for leakage detection no CF 40

Dimensions of MBV-NW SDⅡ-M4Series

| Unit in:mm | ||||||

| Model | MBV-NW25SDⅡ-M4-ARJ | MBV-NW40SDⅡ-M4-ARJ | MBV-NW50SDⅡ-M4-ARJ | MBV-NW63SDⅡ-M4-ARJ | MBV-NW80SDⅡ-M4-ARJ | MBV-NW100SDⅡ-M4-ARJ |

| MOD No | 10822□□ | 10824□□ | 10825□□ | 10826□□ | 10827□□ | 10828□□ |

| A | 40 | 40 | 40 | 40 | 60 | 60 |

| B | 23 | 34 | 52 | 68 | 81 | 104 |

| D | 40 | 55 | 75 | 87 | 114 | 134 |

| G | 0 | 0 | 36 | 56 | 55 | 84 |

| H | 212.5 | 222.5 | 253 | 278.5 | 292.5 | 318 |

| J | 97.5 | 102.5 | 117.5 | 130 | 137.5 | 150 |

| K | 38 | 43 | 58.5 | 71.5 | 78 | 91 |

| L | 90 | 90 | 90 | 90 | 90 | 102 |

Note1:A fully closed type is prepared for NW25 size.

Note2:When installing, use Fuji Technology made Multi-Clump. In case of using other Clumps, there are

some cases where installing is impossible owing to their shape.

<Option>Dual Controller FPC-181S(M4-ARJ)

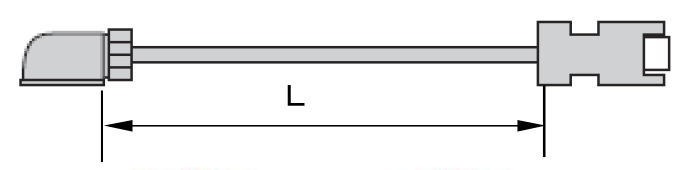

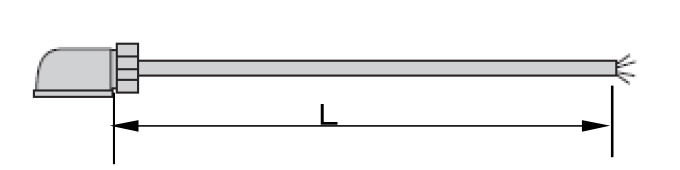

1.ECN cable(load -side /anti-load-side)

Cables for connecting the servo amplifier and valveModele length (L) ECN cable (load -side)2m_4123500 2m ECN cable (load -side)5m_4123501 5m ECN cable (load -side)10m_4123502 10m ECN cable(anti-load-side)2m_4123505 2m ECN cable(anti-load-side)5m_4123506 5m ECN cable(anti-load-side)10m_4123507 10m

Left:load-side-lead Right:opposite to load-side-lead

Left:load-side-lead Right:opposite to load-side-lead

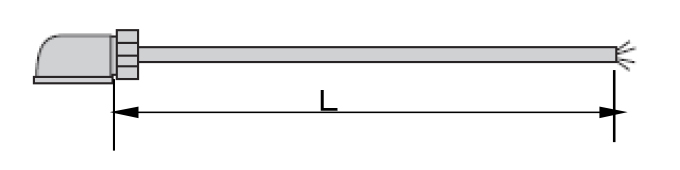

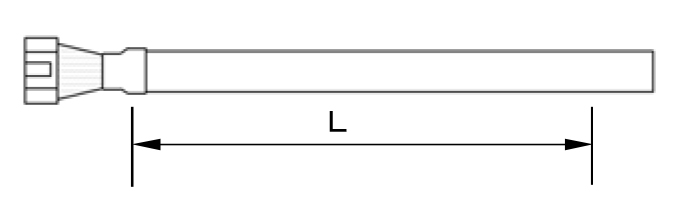

2.MOTpower cable(load -side /anti-load-side)

Cables for connecting the servo amplifier and valve *It is not ashield cableModele length (L) MOT cable(load -side)2m_4123520 2m MOT cable(load -side)5m_4123521 5m MOT cable(load -side)10m_4123522 10m MOT cable(anti-load-side)2m_4123525 2m MOT cable(anti-load-side)5m_4123526 5m MOT cable(anti-load-side10m_4123527 10m  *It is not a shield cable

*It is not a shield cable

3.Electromagnetic brake cable(load -side /anti-load-side)

Servo motor cable with electromagnetic brake. *It is not ashield cableModele length (L) Br cable(load-side)2m_4123540 2m Br cable(load-side)5m_4123541 5m Br cable(load-side)10m_4123542 10m Br cable(anti-load-side)2m_4123545 2m Br cable(anti-load-side)5m_4123546 5m Br cable(anti-load-side)10m_4123547 10m  *It is not a shield cable

*It is not a shield cable

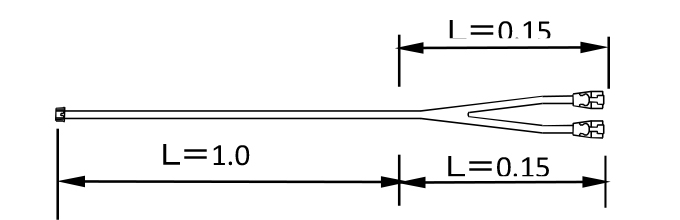

4.SPT-M cable

Cables for connecting the servo amplifier and controllerModele length (L) SPT-M cable_4123051(1.0/0.15m) 1.0/0.15m

5.Analog I/O cable

Cable for Analog I/O to controller (Using 2 axis, 2cables are needed) *shield cableModele length (L) Analog I/O cable_4123314 (2m) 2m Analog I/O cable_4123315(3m) 3m Analog I/O cable_4123316(5m) 5m  *shield cable

*shield cable

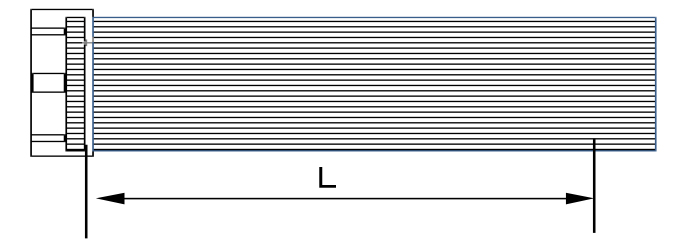

6.-1 REMOTE I/F F cable

Cable for Remote I/O to controller (Flat cable)Modele length (L) REMOTE I/F F cable_4123335(1m) 1m REMOTE I/F F cable_4123336(2m) 2m REMOTE I/F F cable_4123337(3m) 3m REMOTE I/F F cable_4123338(4m) 4m REMOTE I/F F cable_4123339(5m) 5m

6.-2 REMOTE I/F cable

Cable for Remote I/O to controllerModele length (L) REMOTE I/F cable_4123325(1m) 1m REMOTE I/F cable_4123326(2m) 2m REMOTE I/F cable_4123327(3m) 3m REMOTE I/F cable_4123328(4m) 4m REMOTE I/F cable_4123329(5m) 5m